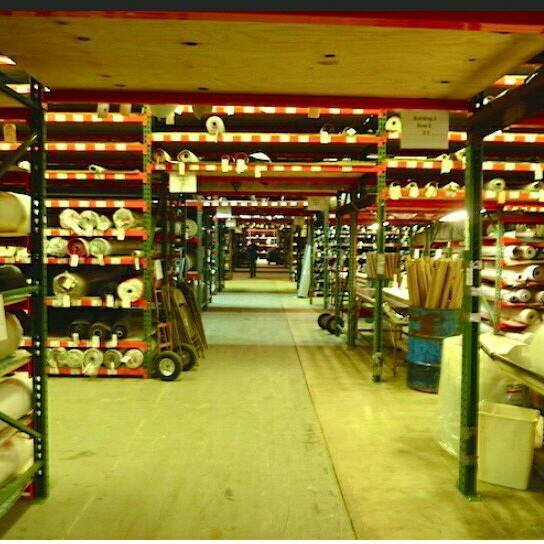

Albright’s Supply is a family-owned distribution business that started in the 1940s. While the company has many products and services one of the main products is upholstery supplies. These supplies are utilized in doing repairs and customizations in automotive, marine, aviation, and furniture. While parts of the business are pure distribution, there are components that are a hybrid and require conversion from one state to another. Being an old-line industry, the sales models or modes of operation had seen little change in fifty years.

In March 2012 a decision was made for a complete makeover. We would evaluate every aspect of the business. Now as 2020 comes to an end, here are some of the changes we made.

- We discontinued the delivery services (several vehicles covering several states) and implemented a Free Shipping Program

- Made an acquisition that doubled the size and expanded into new product offerings

- Custom-developed and ultra-lean dynamic warehousing system that is cloud-based and uses Android devices.

- Build a new high bay warehouse that more than doubles capacity

- Installed a lean cloud-based back office with the latest seamless software that supports all aspects of the operation

These changes have not only increased sales and profits but have created the leanest operation in the industry. For example, two years ago the average pick time approached 20 minutes. Now it is under 3 minutes. As much as 40% of labor was spent looking for items that the computer said were in stock. Now every item is bar-coded with the exact quantity and location. In the process of converting roll goods to orders, there were lots of scrap and waste generated. With the algorithms we have developed we have been able to sustainably improve yield and virtually eliminate waste. The bar-coding has virtually eliminated picking and shipping errors. The number of pickers is now less than half what it was two years ago and the output is more than double. This is mainly because the system sends them to the exact location to get the item they need. If it is a roll, after they have cut off the required amount, the system tells them where to put the roll. It finds the best location based on the frequency of use. This dynamic shifting of inventory keeps the common items in locations closest to the processing stations.

While much of what Creative Solutions does involve laboratory furniture and fume hoods, and lean manufacturing this is an example of how our techniques work across a wide range of industries.

An industry media outlet The Hog Ring did a feature on Albright’s. You can check it out at this link.