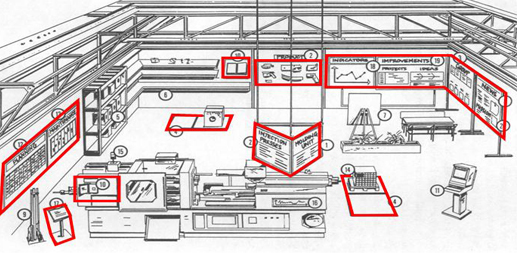

The term “visual workplace” refers to one of the key underlying concepts of lean manufacturing. It refers to a workplace that uses a system of visual cues and visual communication tools that impart information visually at the time and place it is needed. The benefits of having a visual workplace are that it will improve productivity, safety, quality, on-time delivery, profits, and employee morale by implementing “visual controls.”

The term “visual workplace” refers to one of the key underlying concepts of lean manufacturing. It refers to a workplace that uses a system of visual cues and visual communication tools that impart information visually at the time and place it is needed. The benefits of having a visual workplace are that it will improve productivity, safety, quality, on-time delivery, profits, and employee morale by implementing “visual controls.”

Visual controls make working areas user-friendly by answering questions; identifying equipment, materials, and locations; describing actions and procedures; and providing safety warnings and precaution information. Visual controls help employees avoid wasting time by giving them the information they need, where and when they need it.

Until problems are made visible and attract the proper attention, the workforce can’t respond to them. Without the benefits of Visual Management, problems often surface long after the damage is done.

Visual Management with real-time follow-up is another foundational element. Without Visual indicators in real-time, management is left to manage using stale information from the past, sometimes days or weeks old. That’s too late to affect the course the business is heading. It’s like trying to drive your car while only looking in the rear-view mirror.

Creative Solutions can help you create a visual factory that will greatly enhance your performance.